Vibration Analysis

Vibration Analysis

Vibration analysis is a new and powerful tool and is proving to be too valuable to ignore in the operation of your utility system. Developed and applied exclusively by Varius staff, vibration analysis is a true watershed moment in utility planning and operation with the capability to save thousands and improve service.

While vibrations in pumps and motors (all rotating machinery, actually) has been recognized as a source of wear and eventual failure, the tools to be able to analyze exactly what is vibrating, and why, is only now available in economical form. Understanding spectral vibrations (the various frequencies that combine to create the vibration you feel), rather than temporal vibrations (the ones the industry has been measuring), is the key to extending pump and motor life and reducing operating costs. Varius staff have pioneered the measurement and analysis of spectral vibrations, and you can think of this new tool as an MRI for your equipment. Using our proprietary techniques, we can essentially see inside your equipment. We can diagnose hydraulic cavitations at a micro-level, worn bearings, out-of-round shafts, leaking seals, electrical imbalances...virtually any problem that contributes to the eventual failure of your equipment, or contributes to excess energy usage, is discoverable using our spectral vibration analysis tools.

Spectral Vibration Plot - the vibration spikes pinpoint pump and motor problems that will cause early failure.

Pump impeller wear caused by cavitation. Spectral imaging can diagnose this condition before failure.

You can use our vibration analysis capability to reduce your operating costs, to schedule pump and motor replacement when it’s necessary (eliminating the guesswork from how much life is left in your equipment), and to avoid expensive and sometimes catastrophic failures in your system. In addition, you can use our insight into when pumps and motors fail, and why, to create better specifications and longer-lasting pumping systems. We can show you how to specify a pump and motor with a significantly longer life for a surprisingly small increase in cost. Let our experienced staff show you how we can add value to the equipment already in your system.

Spectral vibration sensors temporarily mounted onto a horizontal pump assembly.

Temporal Vibration Plot - Cavitation Signature

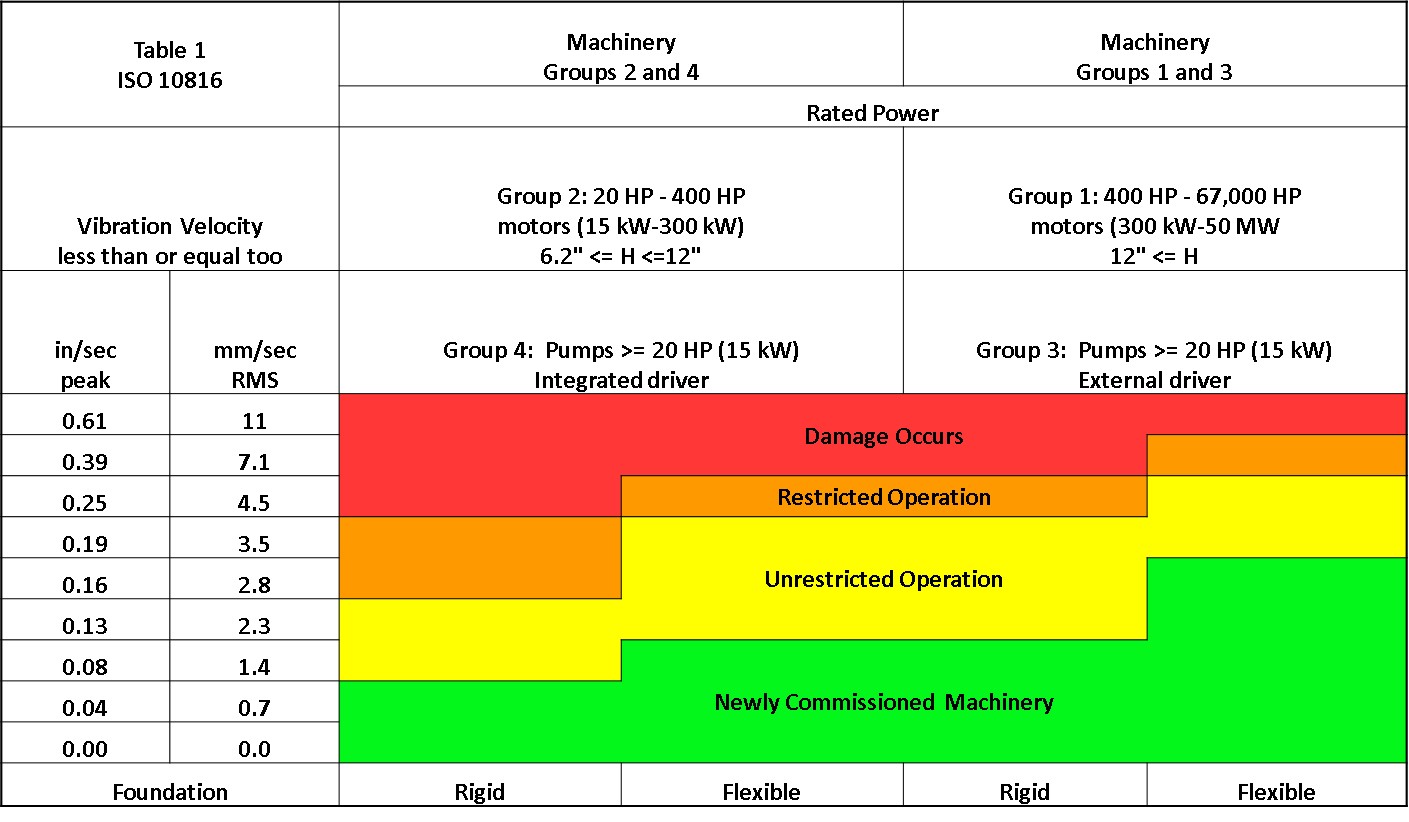

ISO Vibration Tolerance Standards - these are limits established for composite vibration tolerances. Spectral imaging often shows narrow frequency spikes in excess of composite tolerance.